Debugging Method of Cold Roll Forming Machine

The commissioning of Cold Roll Forming Machine needs good working experience. In order to make it more convenient for us to master the debugging method of Cold Roll Forming Machine, we specially compiled the following manual for your reference, introducing some methods of Cold Roll Forming Machine debugging frequently encountered in daily work. The following methods are applicable to roll design, which is reasonable because of the long time, Or not familiar with the cause of debugging confusion, re debugging normal back. However, if the roller design is unreasonable when leaving the factory, it is necessary to modify the roller. If the roller design is unreasonable, it is very difficult to debug. Therefore, if it is a roller problem, the manufacturer should be contacted to modify the roller.

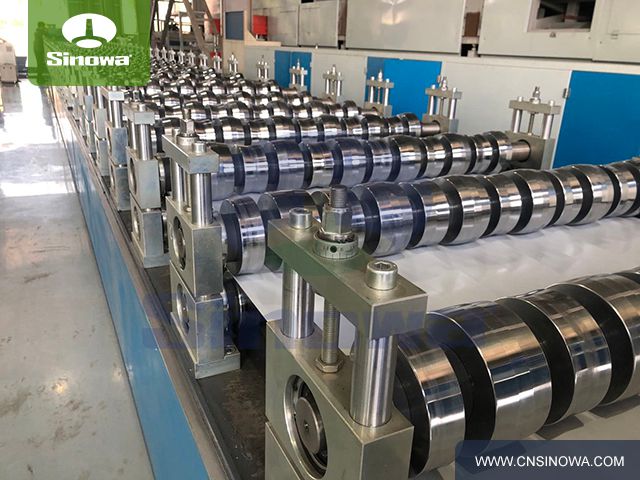

In the daily use of Cold Roll Forming Machine, the common problems are: twist, edge wave, longitudinal bending and so on. Such a problem is that the force on each force point of the roll is not balanced, and the left and right roll deviation is not in a straight line. Therefore, when debugging the cold bending machine, we should grasp a central point to consider the problem, that is, the roller must be in a straight line, and the upper and lower clearance of each group of rolls should be consistent. Therefore, when the Cold Roll Forming Machine has problems, we should focus on this central idea To debug. So, what kind of method can make the roller midpoint in a straight line, and how can the gap between the upper and lower rollers be the same? The following methods will be used for you.

A method of keeping all rolls in a straight line. First determine the first group and the last group of center point, the two groups of roller center point left and right transfer to the center. Then draw a straight line according to these two points. Mark the center point with chalk, and then mark the center point with the center caliper. Mark the center point of all down rolling on the machine in the same way, and then adjust all the center points of the roller to the straight line. After the lower roll is straightened, install it back to the upper roll.

The method of adjusting the gap between the upper and lower rollers. We should prepare a small section of raw materials for production, the thickness of which is consistent with the material used in ordinary times, and then cooperate with a small mirror and a flashlight. Put the material between the upper and lower rollers, and then tighten the screws on the left and right sides at the same time. It should be noted that one side should not be tightened first and then the other side, which may cause the gap on both sides inconsistent. After tightening, use a mirror to look at one side to see if the gap just fits. At the same time, use a flashlight on the other side. If the gap is not uniform, the light transmission will be uneven. After confirming that the gap is even, loosen it a little, and it is appropriate to take out the material just put in. At this time, lock the screws on the left and right sides. Try to adjust the clearance in the same way.

After mastering the above core methods, we should flexibly use different methods for different problems. Sometimes when there are some problems, we can’t pull the straight line again according to the above method every time, which will be very time-consuming and laborious. When there is a slight problem, we can check the material passing through the pass one by one. In this way, we can know from which group the problem began. When the material head just enters the roller, we can roughly see which group is not in the same straight line on-line. Or check the clearance in groups with method 2. When there is twist or edge wave, it may be that a group or groups of left and right pressure are inconsistent or not in a straight line. When longitudinal bending occurs, it may be that some groups of pressure are too tight. You can use different debugging methods according to different situations, slowly summarize, after a period of time, you will be handy.

Page Url: http://www.owsqo.cn/en/debugging-method-of-cold-roll-forming-machine.html